Customized Motorcycle Spare Parts

Customized appearance design of motorcycle parts.

-

01

Customized appearance

For the appearance design of motorcycle parts, we can provide customized appearance design based on your brand style and personalized needs. Whether it's the large components of a motorcycle such as the engine guard plate, wheel hub, and exhaust pipe, or the small components like the dashboard, handlebars, and pedals, we can create a unique appearance for your motorcycle by changing its shape and surface treatment processes (such as painting, chrome plating, carbon fiber texture, etc.). -

02

Function Customization

We are well aware that different customers have varying functional requirements for motorcycle parts, so we offer function customization services. For instance, regarding the suspension system of a motorcycle, we can adjust parameters such as the damping and spring stiffness of the suspension according to your riding style and road conditions, thereby enhancing the handling and comfort of the motorcycle. For the electronic system of motorcycles, we can carry out personalized programming, such as adjusting the throttle response, ignition advance Angle, etc., to meet your performance requirements. -

03

Material customization

In the manufacturing of motorcycle parts, the choice of materials is crucial to the performance and quality of the products. We can choose raw materials of different materials according to your requirements for the production of spare parts. Whether it is high-strength aluminum alloy, carbon fiber composite materials, or high-performance engineering plastics, etc., we can ensure that the spare parts not only meet the performance requirements such as lightweight, high strength, and corrosion resistance, but also meet your customized needs.

Customization process

According to customer needs, we customize various types of tiresfor customers.

Communication requirements

Customers can contact us through online customization forms, emails or phone calls, expressing their demands for motorcycle parts customization and providing detailed information about the parts, such as part names, models, uses, functional requirements, design preferences for appearance, and material requirements. Our customized service team engages in in-depth communication with clients to further clarify their customized intentions and expectations, and to answer their questions regarding product feasibility, technical parameters, cost budgets, and other aspects. Based on the communication results, the customized service team organizes and records the details of the client's requirements, forms a customized requirement document, and prepares for the subsequent design and development work.

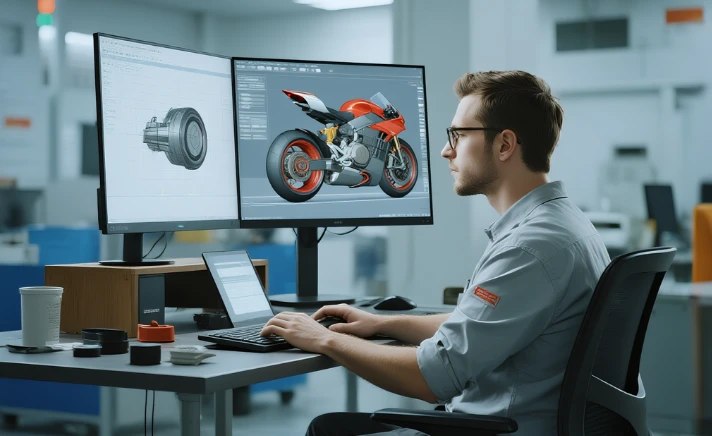

Design and Confirmation

Our professional design team, based on the customized requirements of customers, uses advanced computer-aided design (CAD) and computer-aided engineering (CAE) software to conduct 3D modeling and virtual simulation analysis of motorcycle parts. During the design process, full consideration was given to the structural strength, functional performance, assembly relationship and overall compatibility with the motorcycle of the spare parts. According to the customer's requirements and the characteristics of the product, we select appropriate materials and manufacturing processes and conduct sample trial production. After the trial production is completed, comprehensive performance tests and quality inspections are conducted on the samples, including dimensional accuracy, mechanical properties, durability tests, etc., to verify the feasibility of the design plan and the reliability of the product. Submit the trial production samples to the customer for evaluation and confirmation. Customers can offer suggestions for modification. Our design team will optimize and adjust the product based on the customer's feedback until the customer is satisfied with the product design.

Production and Quality Inspection

The product design plan confirmed by the customer will enter the mass production stage. Our production department arranges production plans based on customization requirements and process documents, and strictly controls every link in the production process to ensure the stability and consistency of product quality. During the production process, the quality inspection team conducts multi-step quality inspections on spare parts, including raw material inspection, semi-finished product inspection during processing, and final inspection of finished products. We employ advanced testing equipment and technologies to precisely measure and strictly control parameters such as the size, shape, and performance of the products, ensuring that the products delivered to customers meet customized standards and quality requirements.

Delivery and Feedback

After the customized production of motorcycle spare parts is completed, we will arrange packaging and shipment in the way specified by the customer, and provide the customer with logistics tracking information in a timely manner to ensure that the products can be safely and accurately delivered to the customer. After receiving the customized spare parts, if customers have any questions or suggestions, they can contact us through our customer service hotline, email or online customer service platform. We attach great importance to customer feedback, actively handle their opinions and suggestions, and constantly improve our customized service process and product quality. Meanwhile, we will communicate with our customers regularly to understand their experience and satisfaction with the customized spare parts, provide them with continuous technical support and services, and consolidate the cooperative and trusting relationship with them.

Get in touch with us

Become the top partner for global motorcycle and electric tricycleparts retailers.